| 9/8/2003 It's my biggest 'Honey Do' home improvement project yet. After months of hints and

prodding, I broke down and agreed to add some living space to our home

by finishing a third of our walk-out basement. The following are logs

that I am making as I go along so that you can check in on my progress

(and let me know of all of those code violations you see :-). By the

way, the reason that we are adding this space now is that we really

needed a separate kids' room and this will serve this purpose well. Log Entry 1: The first thing that was necessary was to

actually make room in the basement given that the area where I was

putting the room housed the pantry, excess furniture, a wall of shelves

and bookcases, and a whole lot of junk. So off I went to the Salvation

Army where I made a number of donations, giving away probably a third of

our 'stuff' so as to make some room.

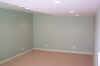

Log Entry 2: Here are some photos of the space that

is being finished off, once I cleared out all of the stuff. The space is

about 12' x 23' with a ceiling of 6.5' under the ducting and 7.5'

otherwise, and will suit a playroom/entertainment room. It has your

typical poured foundation walls and a concrete slab floor. First order of

business: off to Home Depot for some wood!

Log Entry 3: I think they know me by name at the

Depot . . . Anyway, as I started laying out my framing, I took a gander at

potential problem areas; there were four. Here you can see the radon

piping sticking down from the ceiling; it's definitely in the way. Then

there's the water pipe that goes to the outside faucet; it's definitely in

the way as well. There's all of the HVAC ducting, but I'll just need to

frame around it. And finally, there's that I-beam. Now what to do with

that . . .

I cut the radon pipe back and fitted it with the

expandable plug you see below; it's not used nor ever will be, so this

should work fine. As to the water line, I needed to notch out the back

side of the top of the wall I'm framing to account for it, and the arrow

below shows it done. As to the I-beam, I decided to bolt 2x6's onto the

bottom, providing a backing for the drywall and my steel studs that will

be framing out the ducting.

Log Entry 4: The framing has begun. Given the

racket it causes, my wife would like it to be done yesterday; can't say as

I blame her. Here I've completed what I call 'phase 1': framing nearly

three walls including around the window and sliding glass doors (and that

pesky water line). By the way, I've decided to go with a glass block

window to replace the crappy one that's in there now. It's a special order

at Home Depot; should be fun!.

You'll note here that I'm using pressure-treated wood for

the sole plate, positioned about 2" from the wall to allow air

circulation (the gaps behind the walls will be open to the unfinished

portion of the basement), and fastened with powder-actuated fasteners.

Though we have a very dry basement, I've decided to use a drywall primer

that acts as a vapor barrier just to keep any condensation to a minimum if

it occurs at all.

So what are the other phases? Well, phase 2 is to finish

framing out the two side walls under the ducting as well as the last wall

that attaches to the side of the steps. Phase 3 is framing out the ducting

in the ceiling using light-weight steel studs (they could have put the

ducting on the side of the basement opposite the walk-out, but then

builders are like that sometimes; so I'm losing a good amount of headroom

for a third of the room which I'm not too excited about).

Phase 4 is framing out the wall on the opposite side of

the stairs as well as an opening for the steel door that will provide some

noise insulation from the shop on the unfinished side (I do have to say

that I'll miss the natural light that I get coming into the shop now;

can't have it all I guess). I figure it'll take me a week to finish the

framing; then onto flooring, electric, insulation, drywall, trim, painting then

wainscoting. Whew! The end seems so far off.

On a sad note, there was a death today in my power tool family.

You can see it below giving up the ghost. This offers an opportunity for

me to espouse my tools philosophy of always spending the money for good

tools because they will be a pleasure to use and will stay around for a

good long time. Usually I adhere to my own advice, but I decided to buy

this imported Chicago-brand recip saw from Harbor Freight, thinking that I

don't use recip saws very often, and it died today after little use. So

now I'm going with a P-C TigerClaw that will also allow me to get in

between the studs with its unique twisting action. Just a thought for you

for your next holiday/birthday/anniversary gift (you can buy yours here!).

Log Entry 5: I finished framing out around the

stairs. I'm 95% done with framing; only have the door to the shop to frame

out and then my wife will be very pleased as the noisy part will mostly be

over. The stairs were a little tricky; on the other side there are low

joist hangers and ducting to account for, and on the near side I went with

2x6s for part of the wall to steady the stairs. Once I get drywall and

ballisters up it'll start looking pretty good.

Log Entry 6: I finally finished the $%*&!!@

ceiling framing. Not having worked with steel studs before, it wasn't too

bad; easier than I thought it'd be. The problem came when I went to lift

and attach each of the two assemblies to the ceiling and side wall track.

Needless to say, this is a two-person job, however I'm not one to wait for

help when I know it won't come for 24 hours, so after a whole lot of

effort I finally got everything hung. The casualty was the outside track

in the right picture below. In the end it was so twisted that I had to

replace it with another, straight track, once it was up. This is where the drywall will

attach so it's important that it be straight. I would recommend working

with steel studs; they are so much lighter than wood, and 40% cheaper as

well. Plus, if you do something wrong, it's much easier to reverse things;

just unscrew a screw. On to hanging the lights, outlets, switches and

wiring . . .

Log Entry 7: Today I finally finished framing the

area around the stairs and the door to the shop. You can see the result of

my effort below. I've also roughed out most of the wiring and

junction/outlet boxes. It was a nice break from framing while I waited for

my Porter-Cable TigerClaw to be delivered from Amazon. Allow me to digress

by talking briefly about this saw. It's great! The ability to rotate the

blade in both planes allows you to do most any recip job with ease. I

would highly recommend this saw. The only downside to it is the vibration.

If you'll be using one all day long I would recommend those gel

anti-vibration gloves.

As to the wiring (I won't fess up to having to wire all of

the [insulation-rated] recessed lights twice; code requires wires to be clamped, you see . .

.), what's left is the trickiest part: installing two sconce lamps and

switches in the stairway, relocating the ceiling light and smoke detector

below, rewiring the circuit for the lights in the unfinished part of the

basement, installing the breakers, and building a false ceiling to accommodate

the junction box for a light I'm putting up in the landing of the stairs.

You can see in the last picture on the right, that the two joist spaces

that would have accepted this box both have ducting in them (one is

covered by fiberglass). Hurdles like these seem to always be popping up,

which tends to get a little tedious. By the way, I'm going with a 20 amp

circuit for the outlets; eight in total. You never know what type of home

entertainment system will eventually be placed in the room, so it's better

to go with overkill than not have enough amperage. 20 amps will give you

20x120v=2,400 watts. The rule is to max out at 80% which works out to a

common rule of 100 watts per amp; plenty for my dream system!

By the way, if you would like a TigerClaw of your own, did

I mention that you could buy it here?

Log Entry 8: Finally, with the completion of the

stairwell wiring and false ceiling above the bottom landing that you can

see below, all pre-drywall wiring is now complete. Over all, two new

circuits were installed, another rewired and new multimedia lines were

threaded for future multimedia needs. In the picture on the right you can

see the speaker wires, cable and phone lines, and CAT-5e wiring that has

been threaded from a router upstairs, through the attic, down the PVC pipe

and into the wall. Last steps before insulation is moving the hard-wired

smoke detector and framing out the two HVAC

vents.

Log Entry 9 - 10/6/03: Well, it's been a month

since I first started this project. Let me pause to take a breather . . .

Okay, having moved the smoke detector and having framed out the two HVAC

vents, in the picture at left below, I was ready to start putting up the

insulation. Over the course of the next two days, I reached another

milestone, having completely installed the insulation (I chose to use the

encapsulated stuff; it's more expensive but much less of a mess, although

having to tear the batting in half to get around the electrical wiring

defeated some of this benefit).

For the first time you can get a good perspective on the

definition of the room size. In the third

picture you can also get a glimpse of my shop pooch; our toy/miniature

poodle whose company we have enjoyed for over eight years. Next stop?

Putting the ceiling drywall up. I'm hoping that doesn't take more than a

couple of days.

Log Entry 10 - 10/10/03: Phase one of project 'hang

drywall' is complete; that is, the ceiling and two of the four walls have

been hung. With the help of a couple friends, Mike D. and Mike S., it only took about six

hours. Phase two, the balance of the hanging, will go up later this week.

Then it will be on to taping; any volunteers??

Log Entry 11 - 10/25/03: It's been two weeks and I

am pleased to say that phase two of the drywall is complete; all walls are

hung and the taping and spackling is nearly done. I paid a friend of mine

to do this as 1) I'm not the greatest spackler and 2) I hate doing it

(perhaps the two are related??). Thanks Dave G. for helping out. By the way,

let me recommend the vinyl beading that adheres to the drywall with an

adhesive spray. So much easier than screwing metal beading on.

The first photo below is of the original basement window;

the typical cheap pull-out type found in most of America's basements (yep,

that's me in the reflection taking the picture). I chose to replace it

with a custom-made glass block window from Home Depot. You can see it

below as well. I thought it was reasonable for about $85 and adds a lot to

the looks of the room. Thanks to Tom L. for his skills in putting it in. Dave

and Tom both did a great job.

Once the final sanding is complete, it'll be time to paint

on the drywall sealer; it's a special sealer from Benjamin Moore that acts

as a vapor barrier, and after that it'll really start looking like a real room.

Log Entry 12 - 11/2/03: The final sanding. sweeping

and cleaning up of spackle from the floor, is finally done. Today the

first coat of sealer will go up. I'm anxious to see how well the sealer

hides the tape marks, small imperfections and such. We also were out

shopping for carpet and paint. The end is in sight and I can't wait to

move the furniture in and take a nap!

Log Entry 13 - 11/17/03: The paint is now up and I

think the sage green my wife picked out looks great. I pre-painted all of

the trim a cream-like color; it's a pleasing combination. The sconce

lights in the stairwell turned out well also. Now we wait for the carpet

to go in tomorrow. Then it's onto the trim and it'll just be about

finished. One note: I found out the hard way that you really need to screw

the banister to the wall; nails don't provide enough holding strength to

withstand the stress that a stair rail receives through daily use.

Log Entry 14 - 11/20/03: Now that the baseboard and

trim is finished (definitely put up the trim before the carpet goes down

or you'll end up with gaps where the floor is uneven) and the carpet is down, the following pictures are of the

finished room; both without and with furniture. It's amazing how the room

shrinks when you put furniture in it. The couch is a pull-out

queen sleeper for when guests come over (the love seat is really a

sage green though it looks brown in the photo). The matching sofa table is

where I put my wide-screen 43" DLP television (if you're thinking of

going plasma, bear in mind that plasma screens are more expensive and

susceptible to burn-in, a risk you take when playing games on your

PlayStation or if you don't stretch width-wise all of the non-high

definition programming). By the way, if you've viewed our

Jamaica vacation

pictures, that giraffe in the corner will look familiar. EDIT: It is now

19 years later and I gave away my $4,000 DLP television that was cutting

edge back in the day and replaced it with a smart TCL 4K flat screen.

Smart TVs are great!

All in all, I don't know if I'd tackle this home

improvement project again

if I could actually afford to have someone do it for me, but it's sure

been a learning experience. Well, on to the next honey-do project I guess!

|